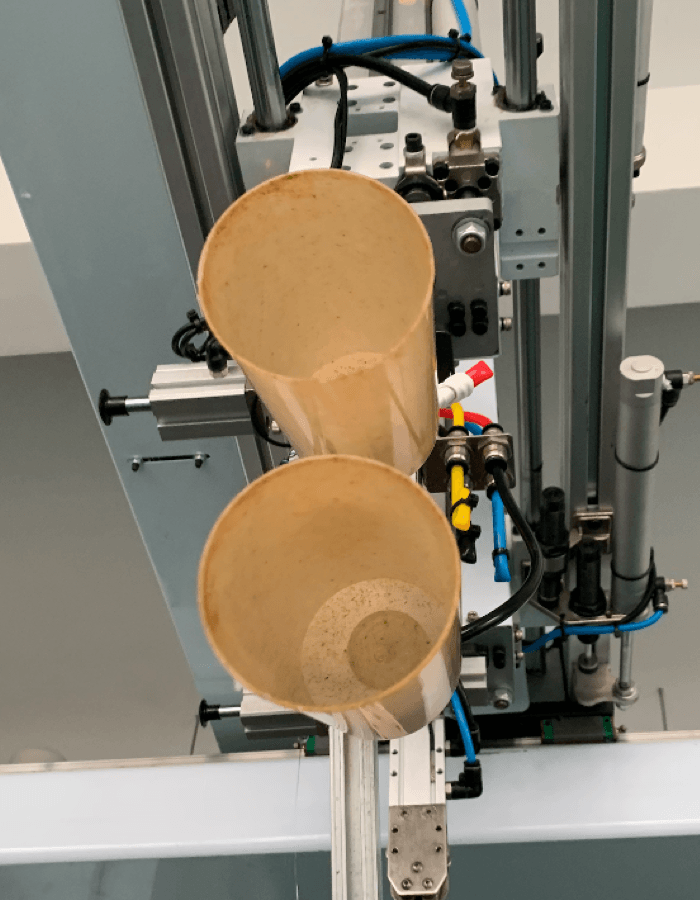

Biomaterials

High-Performance Composites

Mottainai 5.0 Upcycling

Where Sustainability Drives High Performance

We Help Product-Driven Companies

Innovate, Cut Costs, and Decarbonize

Decarbonize Inputs with Biomaterials & Mottainai 5.0 Upcycling

Decarbonize Outputs with High-Performance Composites

Reshape Supply Chains for a Circular & Low-Carbon Future

Community

Consulting & Retainer

Technology

Community I Consulting I Licensing

Sustainable Material Implementation

Fails for These Reasons

Knowledge Gaps Lack of in-house expertise to engineer, test, and validate new materials

Economic Barriers High material costs, price volatility, complex supply chains, and unproven scalability.

Manufacturing Hurdles Complex processing requirements and manufacturing hurdles.

Compliance Risks Navigating complex regulations, certifications, greenwashing claims, and end-of-life waste gaps.

Even companies that validate sustainable materials struggle with implementation.

We help overcome these barriers.

Simplify the process, minimize risks, and ensure a smooth path to decarbonization.

Make Biomaterials & High-Performance Composites Work

Accelerate Innovation and Brand Awareness

Community

Materials

The Sustainable Materials Community: Your direct access to expert guidance and industrial solutions for sustainable, high-performing materials, upcycling, and effective decarbonization. Get ongoing strategies, implement with confidence, achieve tangible results, and stay empowered to innovate.

Consulting

& Retainers

Tackle your specific material challenges. Access practical expertise via consulting projects or retainers. We diagnose pain points and engineer tailored strategies for supply chains, materials, and products, driving implementation for measurable gains in innovation, cost reduction, and decarbonization.

Technology

Licensing

License exclusive, high-value IP for a distinct competitive advantage. Access proprietary material formulations, advanced processing tech, and unique circular business models like Mottainai 5.0™, developed via extensive industrial R&D. These technologies will accelerate your sustainable products.

Proven Experience

With Industry Leaders and Brands

Academic and Industry

Labels and Recognitions

Acknowledged as a player in biomaterials and the circular economy, NATURE2WORLD's experience centers on transforming organic residues and fibers into value-added bio-materials for diverse applications. They deliver expertise in material formulation, focusing on recyclability, energy efficiency, and meeting market needs for sustainable solutions.

Liège Université

Belgium

Validated by the Solar Impulse Foundation, Mottainai 5.0 carries the Efficient Solution Label, confirming the framework meets high standards of sustainability performance and profitability. This label assures clients that NATURE2WORLD's innovations are not only environmentally sound and economically viable but also ready for scalable impact.

SOLARIMPULSE FOUNDATION

Switzerland

Join the Movement

Get Expert Insights on Biomaterials & Performance Composites.

By submitting your information, you agree to receive news, updates, and promotional material. You can unsubscribe at any time.

All Rights Reserved.

© NATURE2NEED BIOMATERIALS